Revolutionizing Warehouse Operations: The Power of Electric Forklift Lithium Batteries

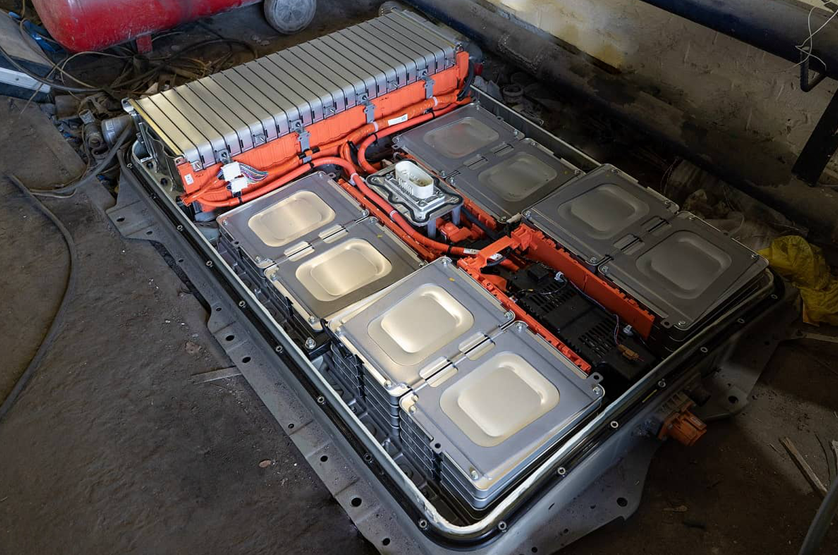

In recent years, the advent of electric forklifts has revolutionized the way warehouse operations are conducted. These environmentally friendly and cost-effective solutions have proven to be a game-changer in the material handling industry. One of the key components that have contributed to their success is the use of литиевые батареи.

Lithium batteries have gained popularity in various industries due to their numerous advantages over traditional lead-acid batteries. In the case of electric forklifts, these batteries provide improved performance, longer lifespan, and increased efficiency.

First and foremost, lithium batteries offer enhanced performance compared to their lead-acid counterparts. They provide a consistent and steady power supply, ensuring that the forklift operates at its optimum level throughout its operation. This not only improves productivity but also ensures the safety of the operators by reducing the risk of sudden power failures or performance fluctuations.

Moreover, lithium batteries have a significantly longer lifespan compared to lead-acid batteries. While lead-acid batteries typically last between 1,000 and 1,500 charge cycles, lithium batteries can endure up to 3,000 charge cycles or more. This extended lifespan translates into reduced maintenance and replacement costs, as well as less downtime for the forklifts.

Additionally, the use of lithium batteries in electric forklifts results in increased efficiency. Unlike lead-acid batteries, which require frequent and lengthy recharging periods, lithium batteries can be recharged quickly, often in less than an hour. This allows for more uptime and reduces the need for additional batteries or backup equipment, ultimately saving time and resources.

Another advantage of lithium batteries is their lightweight nature. Lithium batteries are significantly lighter than lead-acid batteries, meaning that electric forklifts equipped with lithium batteries can carry larger loads without compromising their maneuverability. This, in turn, leads to improved productivity and efficiency in warehouse operations.

Furthermore, литиевые батареи are maintenance-free, eliminating the need for regular maintenance checks and acid replacement as required by lead-acid batteries. This not only reduces operational costs but also minimizes the risk of accidents or injuries caused by battery acid spills.

The environmental benefits of lithium batteries cannot be overlooked either. They are considered a greener alternative to lead-acid batteries due to their higher energy efficiency and lower self-discharge rates. Additionally, lithium batteries are fully recyclable, contributing to a more sustainable and eco-friendly approach to warehouse operations.

Despite these numerous advantages, there are some challenges associated with the use of lithium batteries in electric forklifts. The initial investment cost of lithium batteries is higher than that of lead-acid batteries. However, considering the long-term benefits and cost savings, this investment is often worthwhile for companies in the long run.

Furthermore, given the relatively new technology, there may be concerns about the availability and accessibility of lithium batteries. However, as the demand for electric forklifts continues to grow, the market for lithium batteries is expanding rapidly, making them more readily available and affordable.

In conclusion, the use of lithium batteries in electric forklifts has revolutionized warehouse operations. These batteries offer improved performance, longer lifespan, increased efficiency, and environmental benefits. While there may be initial investment costs and concerns about accessibility, the long-term advantages make литиевые батареи a worthwhile investment. As the material handling industry continues to evolve, companies should embrace this technological advancement to enhance their warehouse operations and stay ahead of the competition.

-

Введение. Медицинское оборудование играет решающую роль в медицинских учреждениях, помогая медицинским работникам ставить точный диагноз, выполнять жизненно важные процедуры и контролировать состояние пациентов. Для обеспечения бесперебойной работы этих устройств необходимы надежные и долговечные источники питания. Литиевые батареи изменили правила игры в медицинской промышленности, предлагая значительные технологические достижения, повышающие как производительность, так и безопасность....Читать далее

Введение. Медицинское оборудование играет решающую роль в медицинских учреждениях, помогая медицинским работникам ставить точный диагноз, выполнять жизненно важные процедуры и контролировать состояние пациентов. Для обеспечения бесперебойной работы этих устройств необходимы надежные и долговечные источники питания. Литиевые батареи изменили правила игры в медицинской промышленности, предлагая значительные технологические достижения, повышающие как производительность, так и безопасность....Читать далее -

In today's modern world, the demand for high-capacity batteries has increased exponentially. As we rely more on portable devices and renewable energy sources, the need for long-lasting energy solutions has become crucial. One such solution is the high-capacity 12V LiFePO4 battery, which offers 100Ah power to meet our energy requirements efficiently. In this article, we will explore the...Читать далее

In today's modern world, the demand for high-capacity batteries has increased exponentially. As we rely more on portable devices and renewable energy sources, the need for long-lasting energy solutions has become crucial. One such solution is the high-capacity 12V LiFePO4 battery, which offers 100Ah power to meet our energy requirements efficiently. In this article, we will explore the...Читать далее -

Когда дело доходит до катания на лодке, крайне важно иметь надежный и эффективный источник энергии. Специально для этой цели разработан пусковой аккумулятор, обеспечивающий необходимую мощность для запуска двигателя вашей лодки. В этой статье мы рассмотрим особенности и преимущества пускового аккумулятора, а также дадим советы, как правильно выбрать его для вашего...Читать далее

Когда дело доходит до катания на лодке, крайне важно иметь надежный и эффективный источник энергии. Специально для этой цели разработан пусковой аккумулятор, обеспечивающий необходимую мощность для запуска двигателя вашей лодки. В этой статье мы рассмотрим особенности и преимущества пускового аккумулятора, а также дадим советы, как правильно выбрать его для вашего...Читать далее -

Введение: Общение играет жизненно важную роль в нашей повседневной жизни. Мы в значительной степени полагаемся на наши смартфоны, планшеты и другие устройства, чтобы оставаться на связи с нашими близкими и получать доступ к информации. За кулисами базовые станции связи служат основой нашей связи, обеспечивая бесперебойное покрытие сети. Традиционно эти базовые станции питались от дизельных генераторов, которые...Читать далее

Введение: Общение играет жизненно важную роль в нашей повседневной жизни. Мы в значительной степени полагаемся на наши смартфоны, планшеты и другие устройства, чтобы оставаться на связи с нашими близкими и получать доступ к информации. За кулисами базовые станции связи служат основой нашей связи, обеспечивая бесперебойное покрытие сети. Традиционно эти базовые станции питались от дизельных генераторов, которые...Читать далее -

The 100Ah 12V LiFePO4 battery is a highly efficient and long-lasting power solution that has been gaining popularity in various industries. This battery is made of Lithium Iron Phosphate, or LiFePO4, which is known for its stability, safety, and durability. One of the main advantages of the 100Ah 12V LiFePO4 battery is its high energy density. This means that...Читать далее

The 100Ah 12V LiFePO4 battery is a highly efficient and long-lasting power solution that has been gaining popularity in various industries. This battery is made of Lithium Iron Phosphate, or LiFePO4, which is known for its stability, safety, and durability. One of the main advantages of the 100Ah 12V LiFePO4 battery is its high energy density. This means that...Читать далее -

When you think of golf, the first thing that might come to mind is a lush green fairway, the sound of a well-struck ball, and the serenity of being out in nature. However, one crucial element that often goes unnoticed but plays a significant role in the golfing experience is the golf cart battery. Without this essential component, your ride...Читать далее

When you think of golf, the first thing that might come to mind is a lush green fairway, the sound of a well-struck ball, and the serenity of being out in nature. However, one crucial element that often goes unnoticed but plays a significant role in the golfing experience is the golf cart battery. Without this essential component, your ride...Читать далее -

Lithium batteries have revolutionized the world of portable power solutions. With their high energy density and long cycle life, they have become the preferred choice for a wide range of applications, from electric vehicles to renewable energy storage. Among the various types of lithium batteries, the 100Ah Lithium Iron Phosphate (LiFePO4) battery stands out for its exceptional performance and reliability....Читать далее

Lithium batteries have revolutionized the world of portable power solutions. With their high energy density and long cycle life, they have become the preferred choice for a wide range of applications, from electric vehicles to renewable energy storage. Among the various types of lithium batteries, the 100Ah Lithium Iron Phosphate (LiFePO4) battery stands out for its exceptional performance and reliability....Читать далее