Revolutionizing the Warehouse: The Advantages of Electric Forklifts with Lithium Batteries

In recent years, there has been a significant shift in the warehouse industry towards the use of electric forklifts with lithium batteries. These innovative machines have revolutionized the way warehouses operate, offering numerous advantages over traditional forklifts. With their improved efficiency, reduced maintenance costs, and environmental benefits, electric forklifts with lithium batteries are becoming the preferred choice for warehouse managers worldwide.

One of the key advantages of electric forklifts with lithium batteries is their improved efficiency. Unlike traditional forklifts that run on diesel or gasoline, electric forklifts operate on electricity, which is a much more cost-effective and efficient power source. Lithium batteries, in particular, offer longer run times and shorter charging times compared to traditional lead-acid batteries. This means that electric forklifts with lithium batteries can spend more time on the warehouse floor, increasing productivity and minimizing downtime for charging or refueling.

Additionally, electric forklifts with lithium batteries require less maintenance compared to their counterparts. Traditional forklifts often require regular maintenance, including oil changes, filter replacements, and engine tune-ups. In contrast, electric forklifts have fewer moving parts and do not require the same level of maintenance. Lithium batteries are also maintenance-free, eliminating the need for battery watering or acid spillage that can occur with lead-acid batteries. This not only saves on maintenance costs but also reduces the time and effort required to keep the forklifts in optimal condition.

Furthermore, electric forklifts with lithium batteries offer environmental benefits that align with the growing trend towards sustainability. Unlike diesel or gasoline-powered forklifts that emit harmful pollutants and contribute to air pollution, electric forklifts produce zero emissions. This not only improves the air quality within the warehouse but also reduces the overall carbon footprint of the operation. Additionally, lithium batteries are recyclable, further reducing their environmental impact. By choosing electric forklifts with lithium batteries, warehouse managers can demonstrate their commitment to environmental stewardship and contribute to a greener future.

In terms of safety, electric forklifts with lithium batteries also have an advantage. Electric forklifts are generally quieter than traditional forklifts, which helps create a less noisy and more productive work environment. The absence of exhaust fumes also improves indoor air quality and reduces the risk of respiratory issues for warehouse employees. Moreover, lithium batteries have built-in safety features, such as thermal management systems, that prevent overcharging and overheating, reducing the risk of battery-related accidents.

Although electric forklifts with lithium batteries offer numerous advantages, there are some considerations to keep in mind. The initial cost of purchasing electric forklifts with lithium batteries is generally higher than that of traditional forklifts. However, the long-term savings in fuel, maintenance, and productivity outweigh the initial investment. Additionally, it is crucial for warehouse managers to ensure that they have an adequate charging infrastructure in place to accommodate the needs of electric forklifts. This includes installing sufficient charging stations and optimizing charging schedules to avoid any disruptions to operations.

In conclusion, electric forklifts with lithium batteries are revolutionizing the warehouse industry. Their improved efficiency, reduced maintenance costs, environmental benefits, and enhanced safety make them the preferred choice for warehouse managers looking to optimize their operations. By investing in electric forklifts with lithium batteries, warehouses can not only improve productivity and reduce costs but also contribute to a more sustainable future. The era of traditional forklifts is fading, and the future of warehousing belongs to electric forklifts.

-

Lithium ion batteries have revolutionized the way we power our everyday devices, from smartphones to electric cars. The most common type of lithium ion battery is the lithium cobalt oxide battery, but there are several other types, each with its own unique advantages and disadvantages. One such type is the lithium iron phosphate (LiFePO4) battery. In this article, we will...Read more

Lithium ion batteries have revolutionized the way we power our everyday devices, from smartphones to electric cars. The most common type of lithium ion battery is the lithium cobalt oxide battery, but there are several other types, each with its own unique advantages and disadvantages. One such type is the lithium iron phosphate (LiFePO4) battery. In this article, we will...Read more -

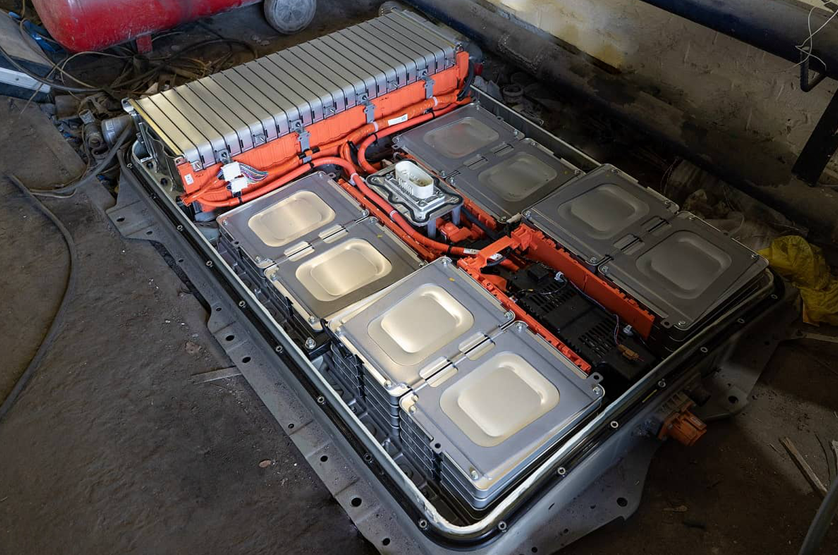

A locomotive starter battery is an essential component of any locomotive engine. Without a reliable power source, the engine cannot be started, and the locomotive cannot move. In this article, we will discuss the importance of a locomotive starter battery and how it works.Firstly, let\'s discuss what a locomotive starter battery is. It is a heavy-duty battery that is designed...Read more

A locomotive starter battery is an essential component of any locomotive engine. Without a reliable power source, the engine cannot be started, and the locomotive cannot move. In this article, we will discuss the importance of a locomotive starter battery and how it works.Firstly, let\'s discuss what a locomotive starter battery is. It is a heavy-duty battery that is designed...Read more -

Introduction As the world continues to grapple with the issue of climate change, the need for eco-friendly solutions has become more apparent. Energy storage is one of the areas where the need for eco-friendly solutions is most pressing. Lithium iron phosphate battery packs are one of the most promising solutions to this problem. In this article, we will explore...Read more

Introduction As the world continues to grapple with the issue of climate change, the need for eco-friendly solutions has become more apparent. Energy storage is one of the areas where the need for eco-friendly solutions is most pressing. Lithium iron phosphate battery packs are one of the most promising solutions to this problem. In this article, we will explore...Read more -

Lithium batteries have become increasingly popular over the years due to their high energy density and long cycle life. They are now commonly used in various applications such as electric vehicles, portable electronics, and renewable energy systems. In some cases, it may be necessary to connect multiple lithium batteries in series to achieve the desired voltage level. However, there are...Read more

Lithium batteries have become increasingly popular over the years due to their high energy density and long cycle life. They are now commonly used in various applications such as electric vehicles, portable electronics, and renewable energy systems. In some cases, it may be necessary to connect multiple lithium batteries in series to achieve the desired voltage level. However, there are...Read more -

Cars require batteries to provide the electrical energy needed to start the engine, power the lights, and operate various electronic components. Starter batteries serve as an essential component in automotive starting systems, enabling the engine to crank up and start quickly and reliably. Choosing the right starter battery supplier is crucial for the optimal performance, safety, and longevity of a...Read more

Cars require batteries to provide the electrical energy needed to start the engine, power the lights, and operate various electronic components. Starter batteries serve as an essential component in automotive starting systems, enabling the engine to crank up and start quickly and reliably. Choosing the right starter battery supplier is crucial for the optimal performance, safety, and longevity of a...Read more -

The importance of having a reliable battery charger for your vehicle cannot be overstated. Whether you are using your vehicle for personal or commercial purposes, a dead battery can cause significant inconvenience and even financial loss. That is why you need an efficient and reliable onboard battery charger like the 24V onboard battery charger to ensure that your vehicle's battery...Read more

The importance of having a reliable battery charger for your vehicle cannot be overstated. Whether you are using your vehicle for personal or commercial purposes, a dead battery can cause significant inconvenience and even financial loss. That is why you need an efficient and reliable onboard battery charger like the 24V onboard battery charger to ensure that your vehicle's battery...Read more -

Introduction In recent years, there has been a growing demand for high-performance batteries that can provide reliable and efficient power for various applications. One such battery technology that has gained significant attention is the Lithium Iron Phosphate (LiFePO4) battery. These batteries offer numerous advantages, including high energy density, longer lifespan, and enhanced safety. To ensure optimal performance and longevity of...Read more

Introduction In recent years, there has been a growing demand for high-performance batteries that can provide reliable and efficient power for various applications. One such battery technology that has gained significant attention is the Lithium Iron Phosphate (LiFePO4) battery. These batteries offer numerous advantages, including high energy density, longer lifespan, and enhanced safety. To ensure optimal performance and longevity of...Read more